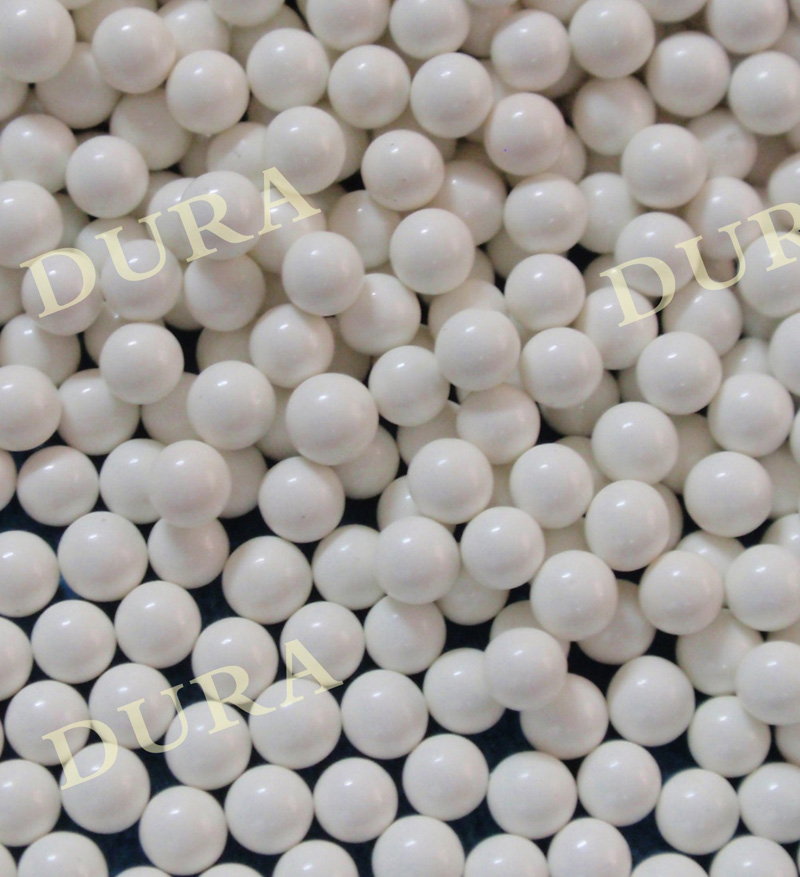

Product : Zirconium Beads : DURA 40

Zirconium Silicate Beads : DURA 40

zirconium silicate beads are made from the high grade Australian zircon sand with granulating shaped method and hardened by sintering. The unique formula and producing procedure offer you a middle density and hardness, high wear resistance zircon beads. It is a good option to grind and disperse middle hard particles in low to middle viscosity range slurries.

Applications:

—Pigments and dyestuffs: to grind and disperse inorganic pigment such as TiO2, carbon black; organic pigments such as phthalocyanine blue, cromophtal yellow;

—Coatings & paints: protection paint, emulsion paint, printing inks, inkjet inks, paper coating and video tape coating;

—Fillers: Kaolin, Mica, CaCO3 and steatite.

Specialty:

—Tight and homogenous microstructure of zirconium silicate;

—Glazed working surface;

—Excellent performance cost;

—Matching mills: discs type of horizontal or vertical bead mills; pin type with the tip speed less 13m/s.

DURA 40 : Zirconium Silicate Beads |

|

Composition |

ZrO2 62-64 %

, SiO2 31-33 % |

| Specification Density (kg/dm3) | 4.1 |

| Bulk Density (kg/L) | 2.5 - 2.6 |

| Hardness (kg/mm2) | 1000 |

| Color | Off-White |

| Standard Size (mm) | 0.4-0.6, 0.6-0.8, 0.8-1.0, 1.0-1.2, 1.2-1.4, 1.4-1.6, 1.6-1.8, 1.8-2.0, 2.0-2.2, 2.2-2.5, 2.5-2.8, 2.8-3.2 |

| Packing (kg) | 25 Kgs Plastic pail |